Mississippi State University

Center for Advanced Vehicular Systems

— MACHINIST & FABRICATOR—

From June 2019 to May 2020, I worked for the Center for Advanced Vehicular Systems (CAVS) at Mississippi State University as a machinist and fabricator. My job required me to design and build components for the materials testing lab on campus. There are four different split Hopkinson bars that I helped create at CAVS: one tension and three compression bars.

Compression Bars

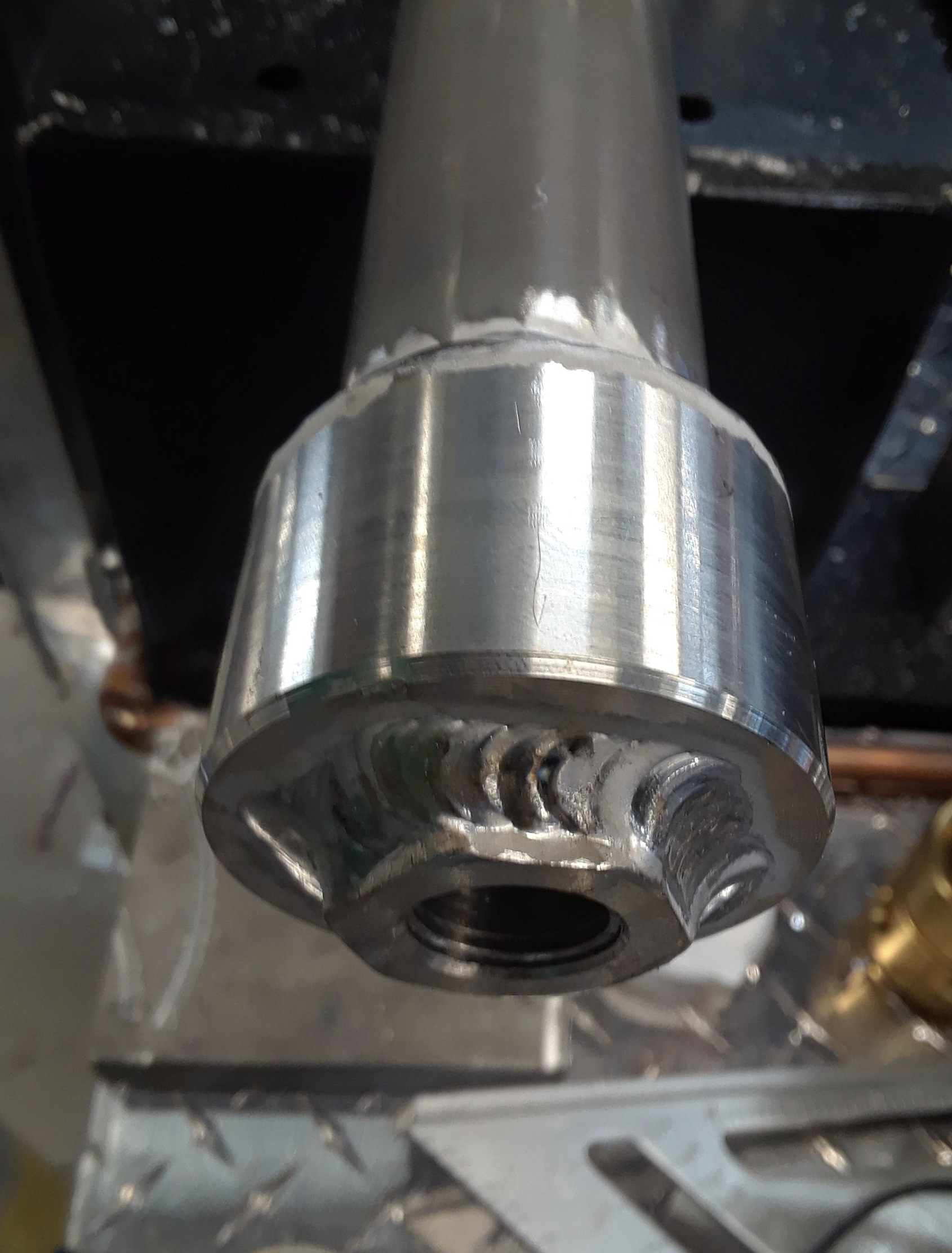

As an undergraduate, I completed a three hour self led design course on re-designing the striker system for these bars. Compression Hopkinson bars use a "striker" to transmit a very powerful impulse through a bar and into a specimen to break it in compression. To do this, a piston is accelerated using compressed gas to high velocities where it slams into a bar to break the specimen. The original design used a 1" diameter piston accelerated horizontally with nitrogen at 200 psi to apply the force to the bar. That system was not strong enough to break harder materials, especially armor steel, so I was tasked with increasing the strength of the test system. To increase the strength, I designed a new system using a 3" diameter striker and 600 psi of pressure. This yields 34 times more energy than the old system. Also, I have designed and built a control panel to make the charge and discharge process much easier.

Tension Bar

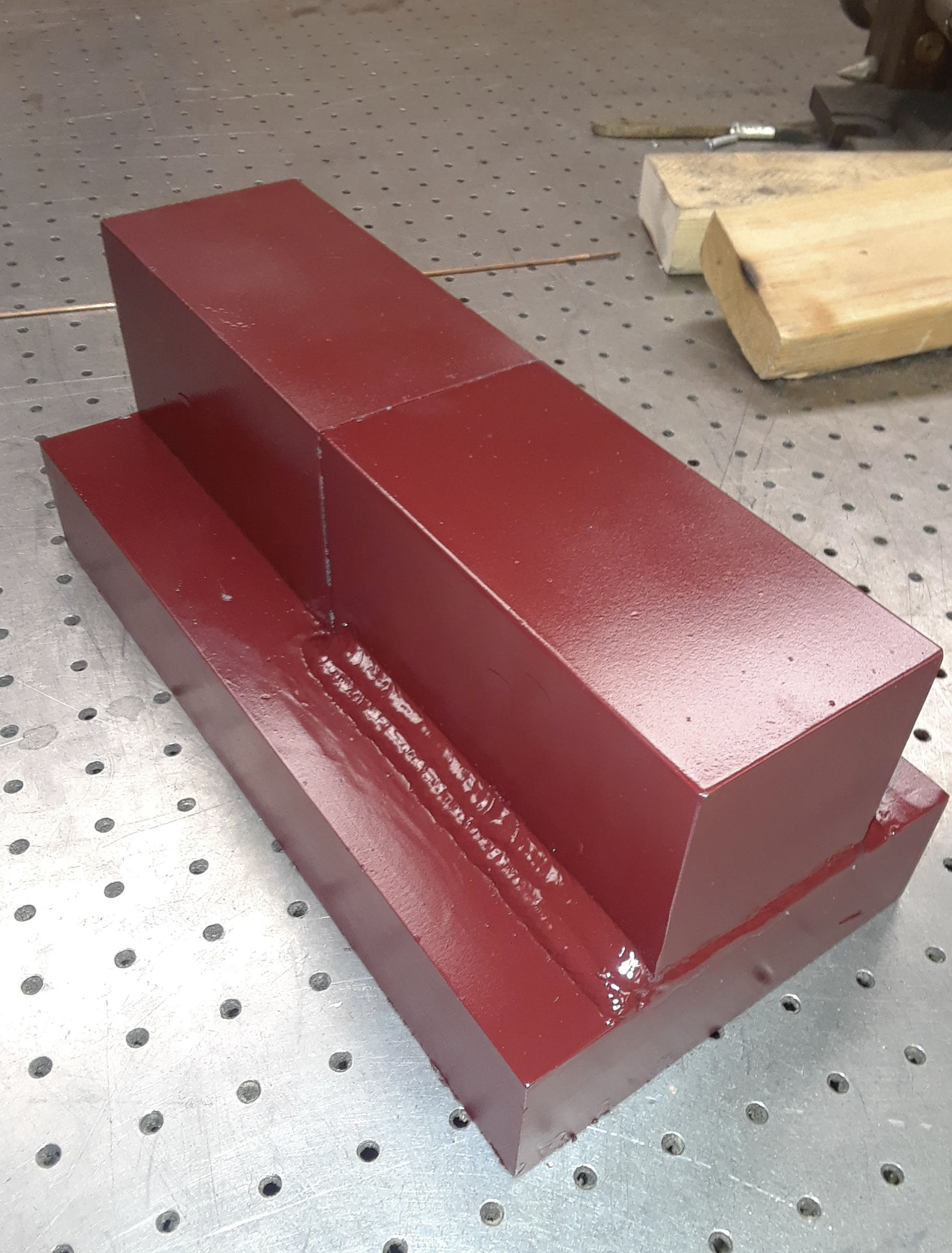

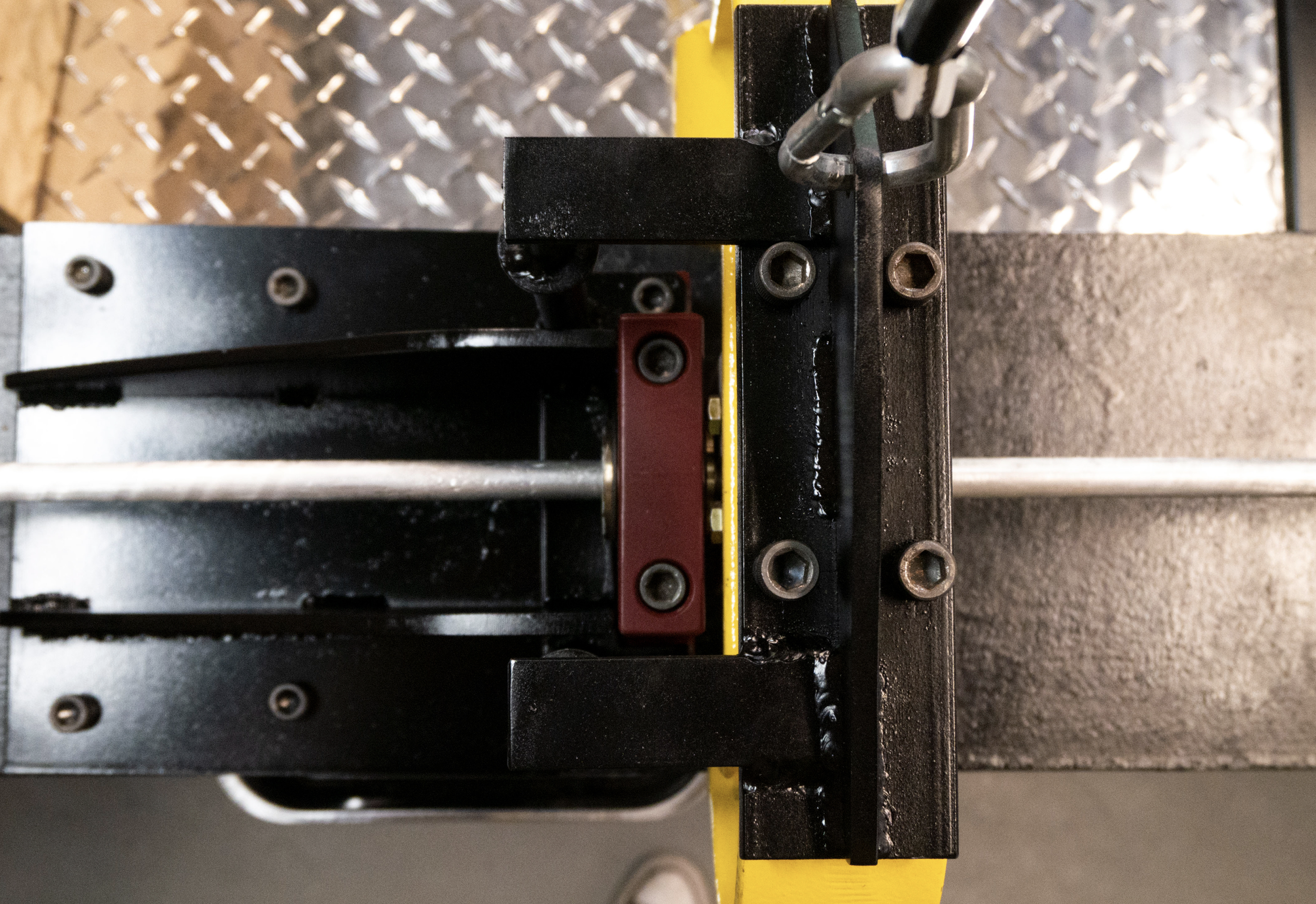

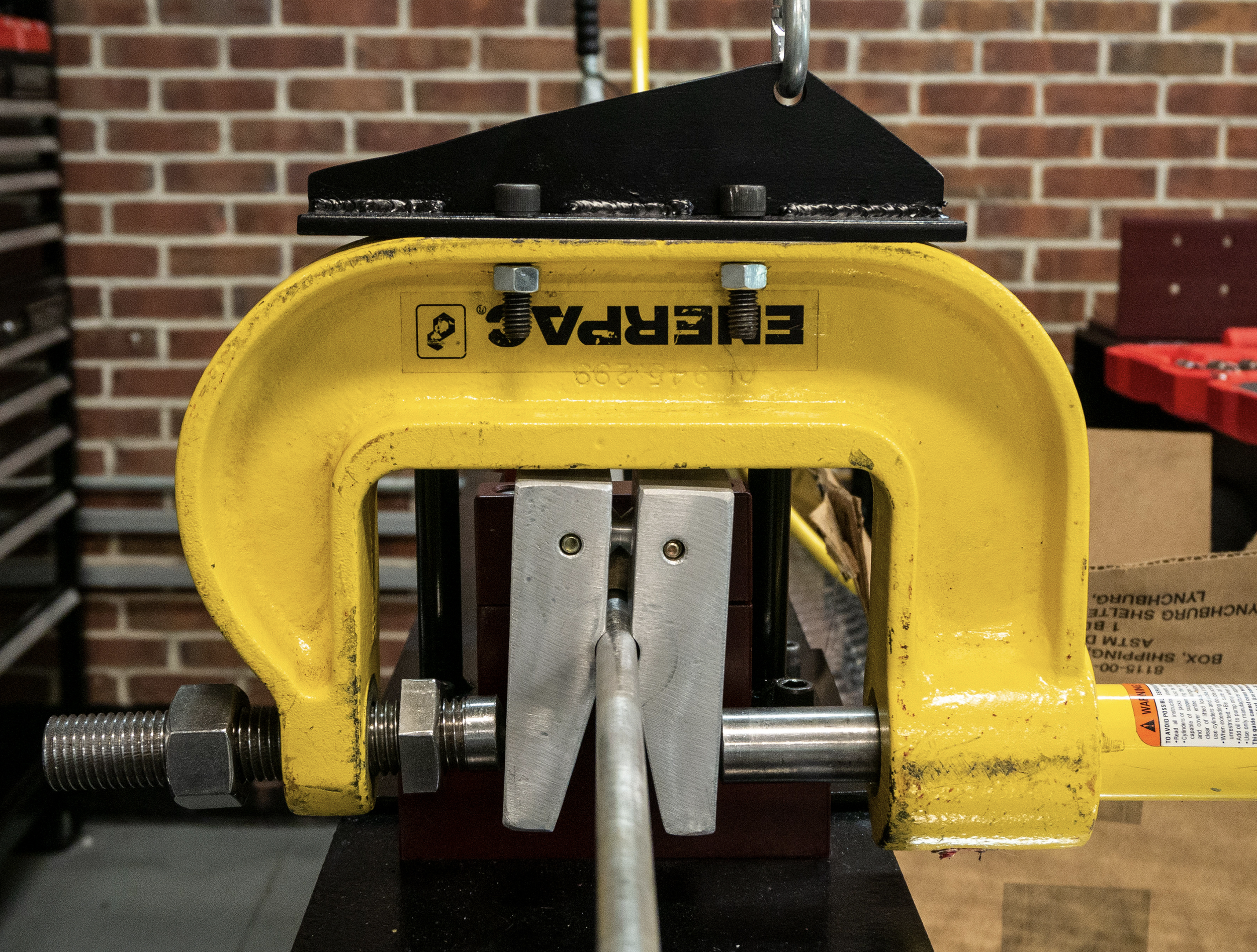

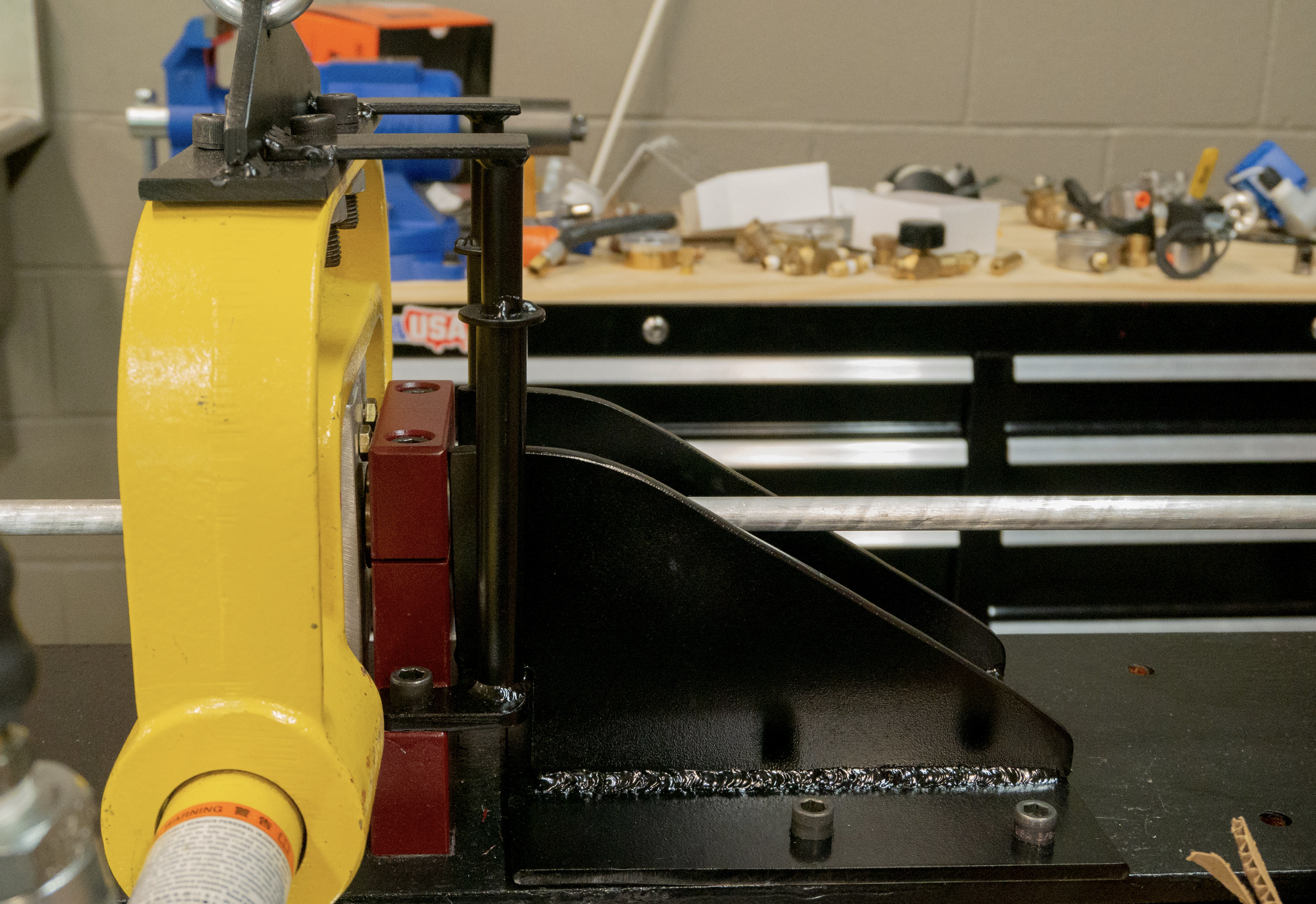

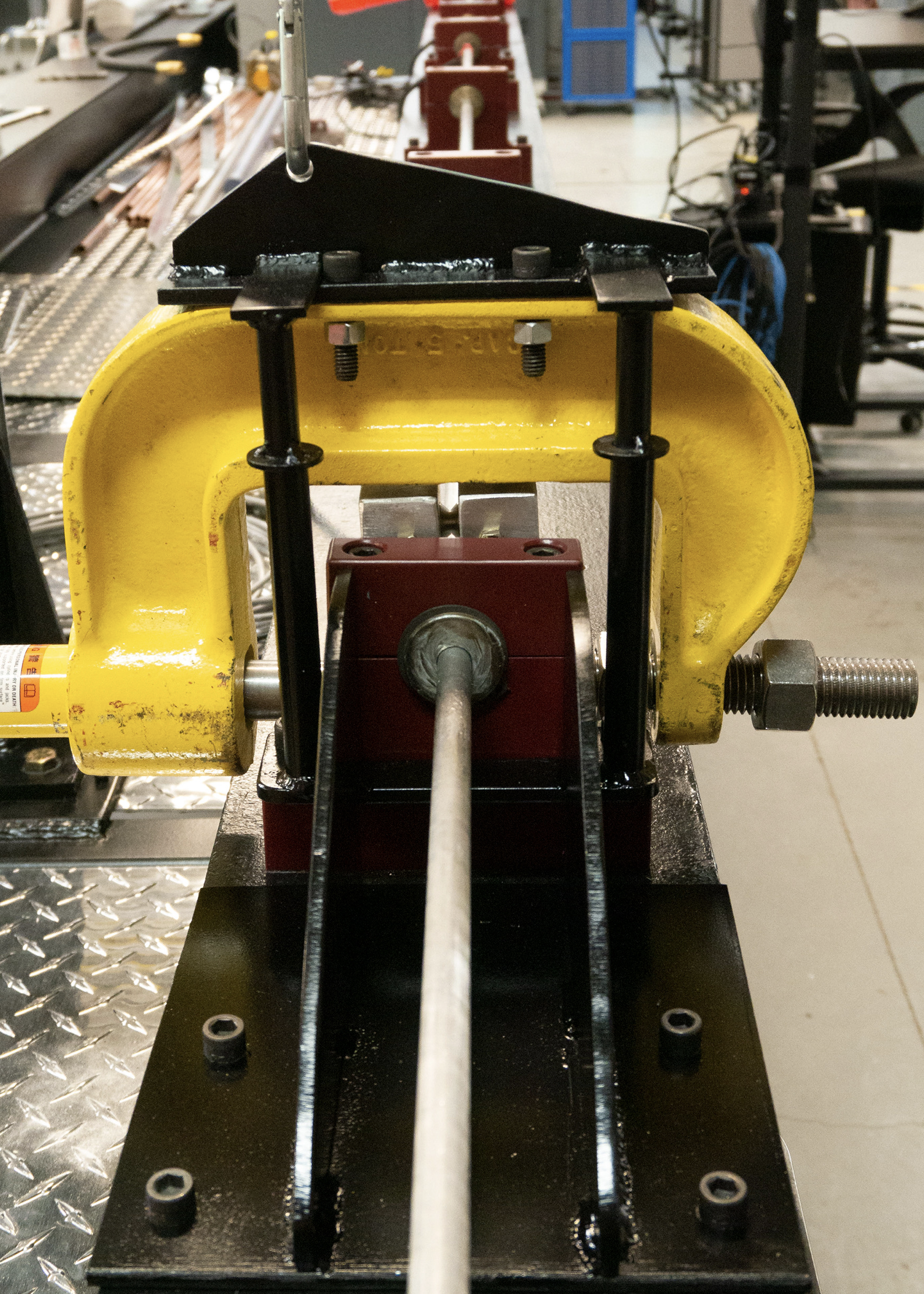

The tension bar at CAVS is a "breaker pin" style bar. That means it uses a clamp to hold back a force applied by an Enerpac ram. Once that force is great enough, the pin holding the clamp together is broken creating an impulse that breaks the specimen. My project was to upgrade the old system with new fixtures to change it from a two person job to a one person job. To do that I designed and built a clamp holder that mounted to the bar and centered the breaker pin clamp on the bar. This new setup allows the operator to place the breaker pin clamp on the bar then actuate the system from a safe distance away. Originally a second operator had to hold the breaker pin clamp in place while the test was conducted.