Hol-mac Corporation

— LEAN MANUFACTURING ENGINEER —

After graduating in the Spring of 2020, I took a job with Hol-Mac Corporation as a lean manufacturing engineer. Hol-Mac is a multi-company corporation that is extremely vertically integrated. Their companies included: Pac-Mac, Donkey Forklifts, Keith Huber Corp., and Hammerhead Armor. During my time there, I helped design multiple tools to assist production. Although, my largest attributes to Hol-Mac was through Hammerhead Armor, I still had a hand in several other projects for the company.

Bumper Slides

The same problem for the packaging line spilled over into the assemble line. To reduce the material handling time of welders and polishers, I designed a slide to move bumpers down the line. Eventually, the bumper slides were placed between every station on the line. I also had jib cranes installed to reduce the use of gantry cranes for loading and unloading bumpers from the slide system.

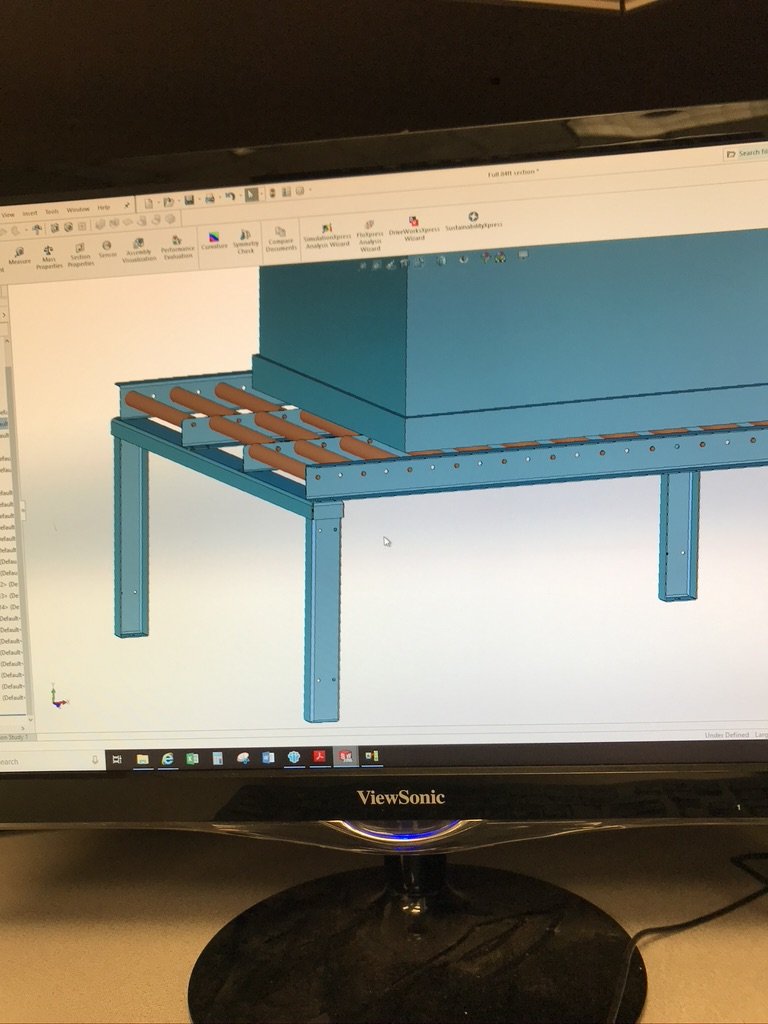

Roller Bed Project

In the Summer of 2020, Hammerhead Armor’s sells were up but production was slow. Our line wasn’t able to keep up with the consistent orders, and it was clearly affecting Hol-Mac. The current production line had did not have an efficient way to move freshly powder-coated bumpers to packaging. Bumpers sat on the ground and took two employees to move; wasting time and money.

I was tasked with designing and building a roller bed for the packaging line to improve the production time. I designed a modular roller bed system that was built in house using laser cut parts and a CNC press brake. In order to save money, I sourced the rollers from old roller beds and designed an electrolysis system to clean the rollers for use. The electrolysis system used a dedicated arc gouging machine at 400 amps to completely clean 6 rollers in 10 minutes. The picture below shows the water boiling as the reaction takes place.

Modular Washer

The largest design project I had at Hol-Mac was a modular washer system for our paint line. I didn’t work at Holmac long enough to finish the design, but my good friend took over the project and did finish it. I can’t take full credit for the finished product, but the overall design was similar to the assembly I had created.