EDELBROCK PREFORMANCE GROUP

— PRODUCT DEVELOPMENT ENGINEER —

In November of 2020, I was given the opportunity to work for Comp Cams as a Product Development Engineer. Like any other car enthusiast, I took the chance without hesitation. It was a life long dream of mine to work in the car world, no matter the specific industry. Soon after I was hired in December, COMP announced the merge with Edelbrock. Since the merge, my title has been Product Development Engineer, but my contributions to the company didn’t stop there. Over the years I have been a design engineer, engine builder, dyno operator, tech, fabricator/machinist and everything in between.

Still being employed by Edelbrock, I continue to preform to the best of my ability on every project and task given to me no matter the circumstances.

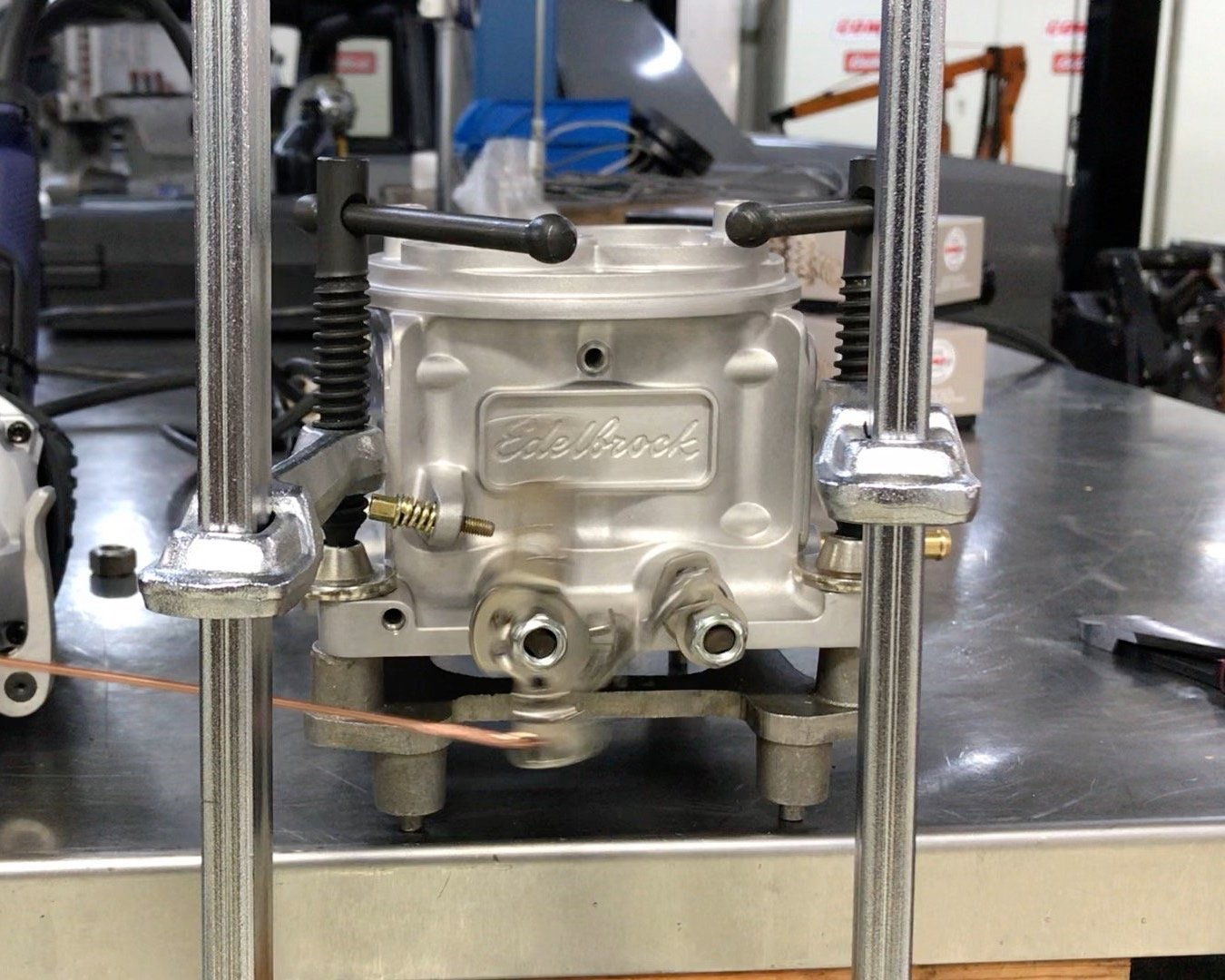

VRS 4150 Carburetor

The VRS 4150 carburetor has been my biggest project. When I was given the project, the design was mostly finished but the carb had never been successfully tested on an engine. Over the next two years, I fixed all the issues with that preliminary design, developed the “out of the box” tuneup, and worked with manufacturing to ensure a high quality product makes it to the customer.

I have also traveled to a number of professional shops and demonstrated the pros of our carburetor versus the competition. I can’t name these shops for privacy reasons, but I can say the VRS has never been out performed on a dyno session I was present at.

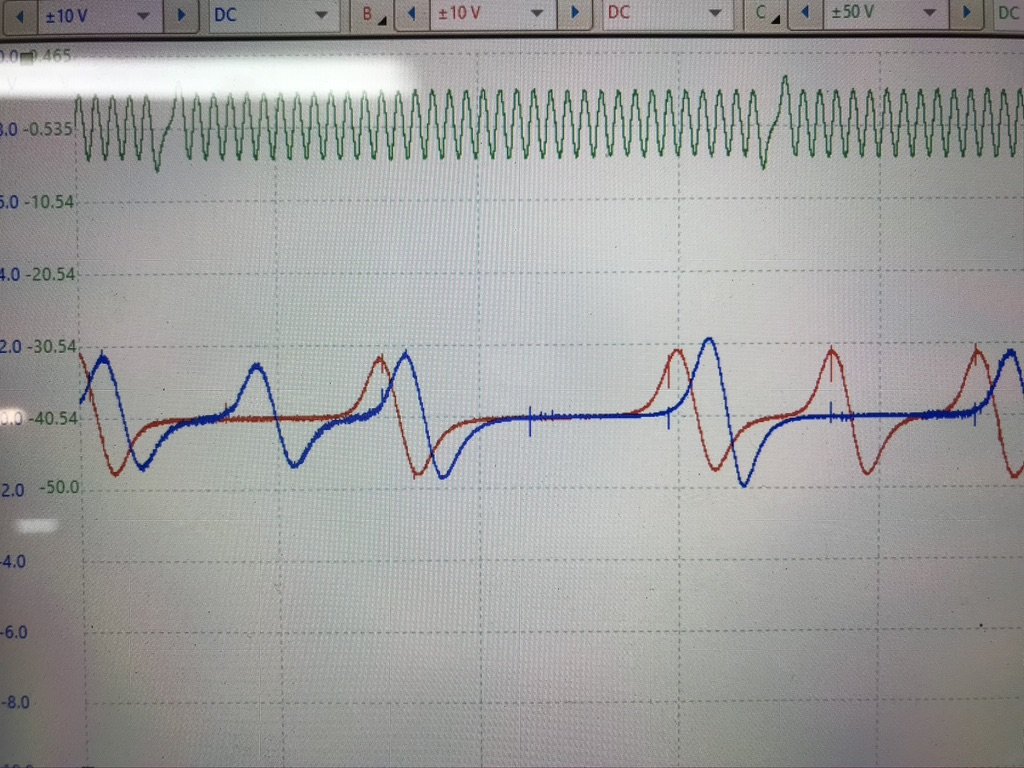

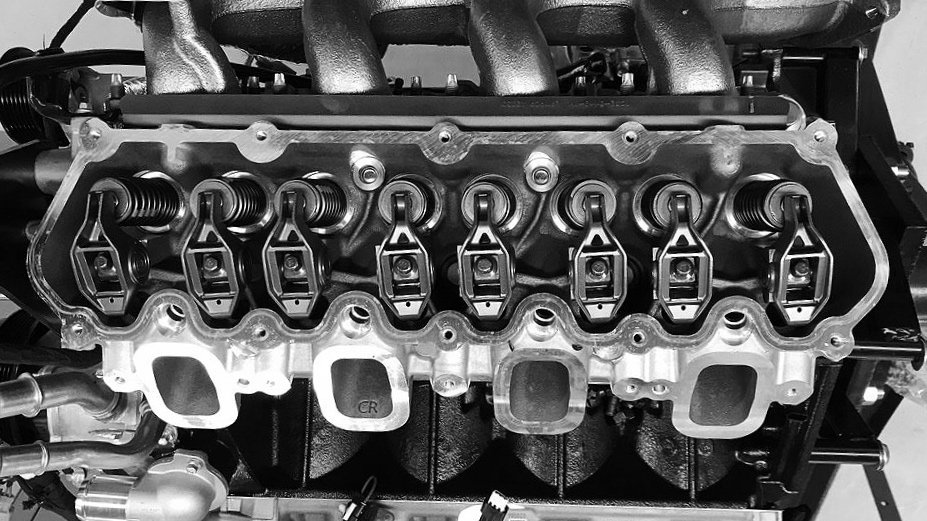

Coyote

The Coyote Project was simple on the design side, but much more technical on the testing side. I modified an existing manifold design to fit in the engine bay of a stock mustang, and was tasked with testing those modifications against the existing part.

From a design side, this project doesn’t prove much, but it does show my resourcefulness as an engineer. I made design changes in Siemens NX (a program I am not extremely comfortable with) then carried out those changes in real life with a plasma cutter and a TIG welder. From there, I swapped camshafts in the test engine (degreed all 4 cams as you should…) and ran that engine on the dyno with a ECU I was not familiar with. I swept the cams and developed a calibration that produced peak power of the engine at all RPMs. I chose to add this project to my portfolio for one reason, I am a make it happen type of engineer who does not back down from a challenge.

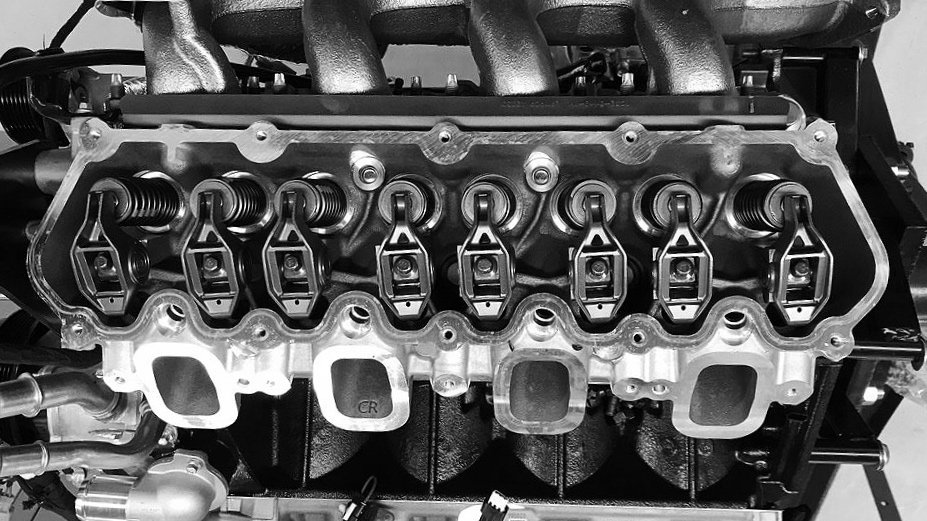

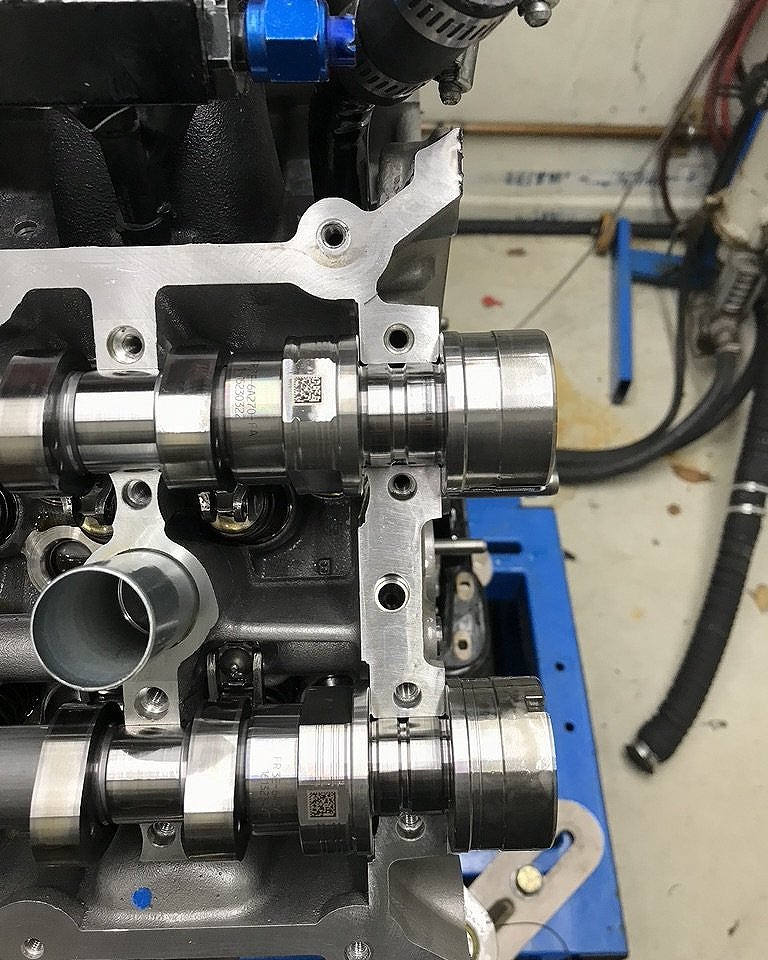

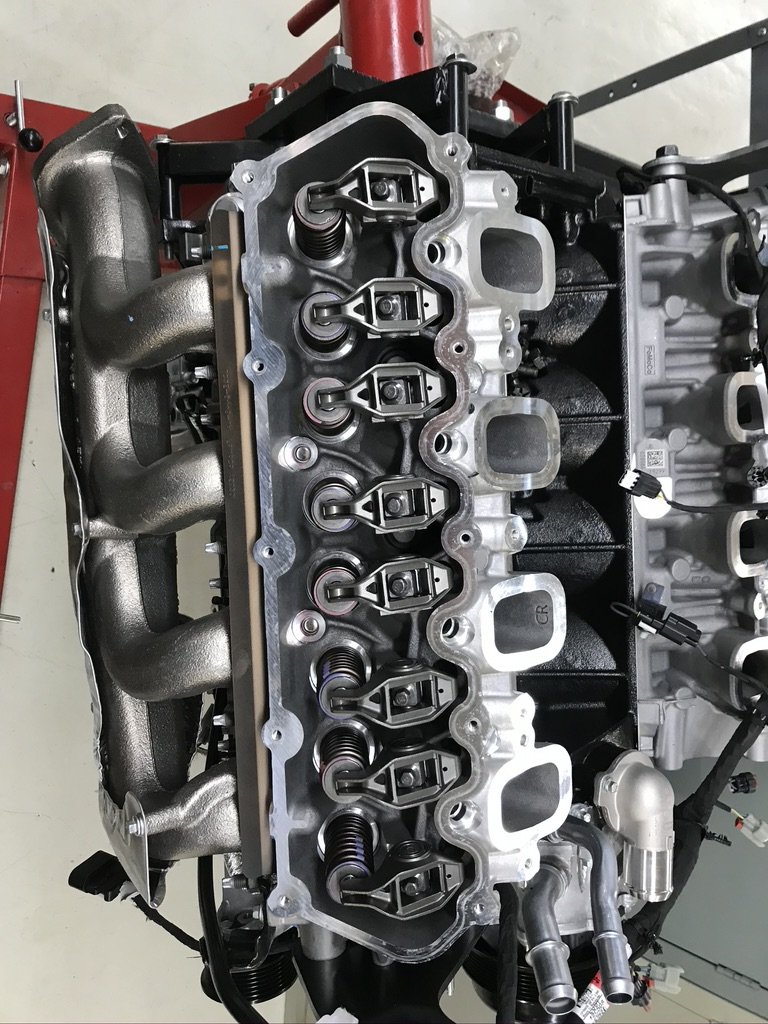

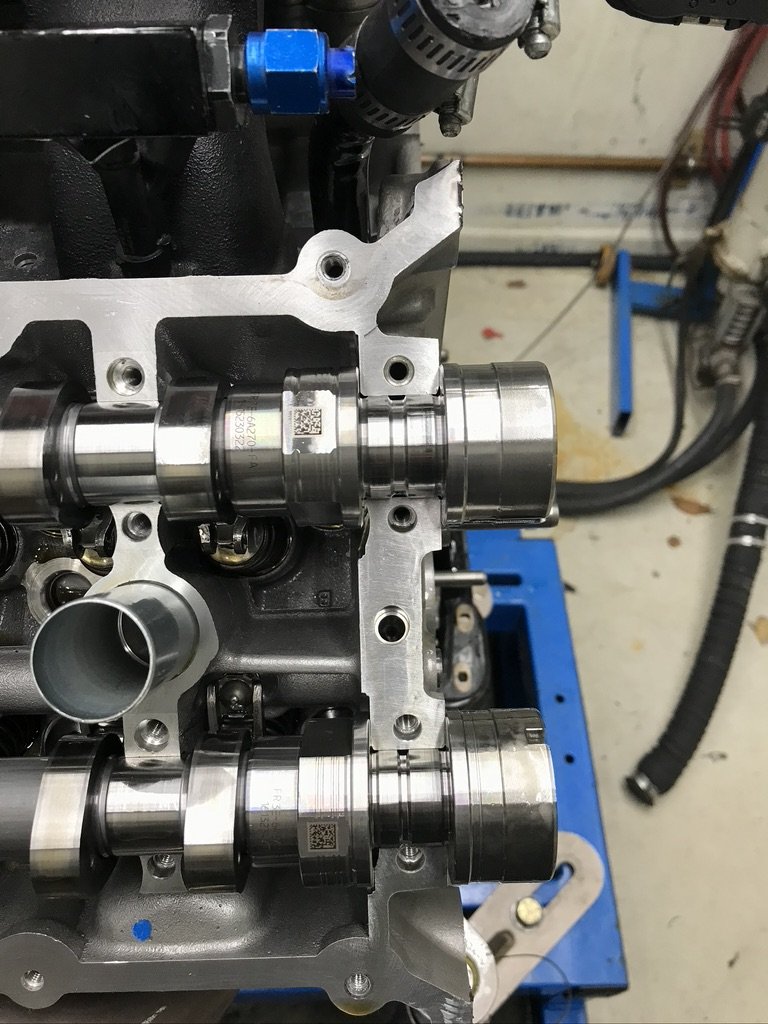

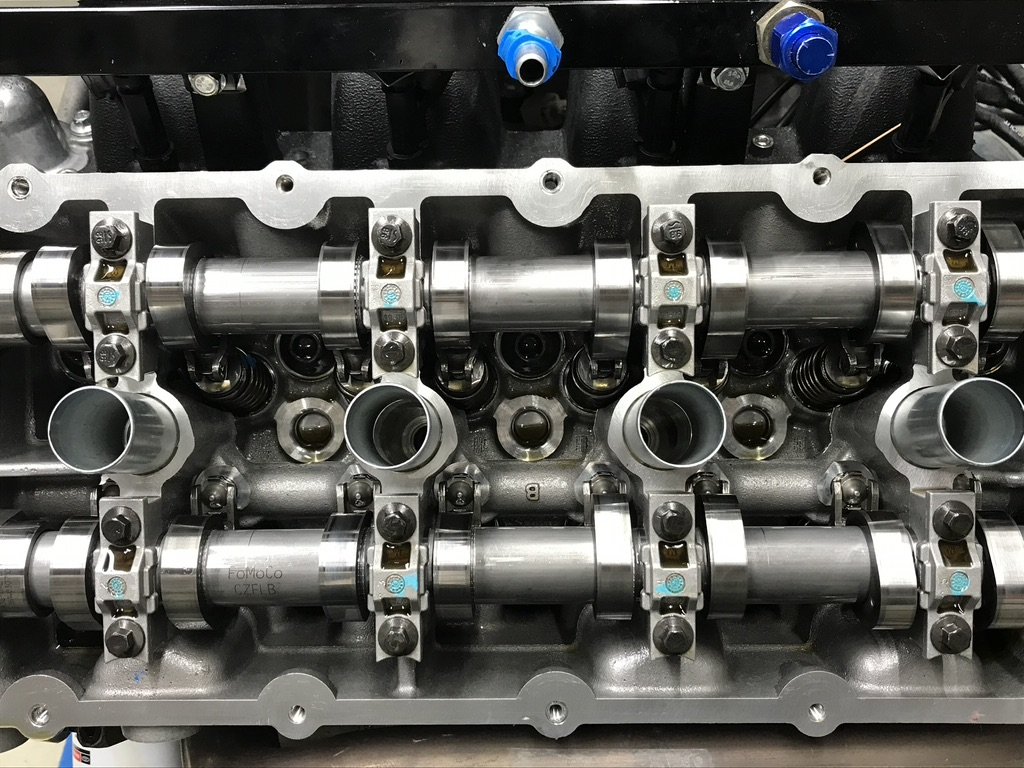

Ford 7.3 Godzilla

My first design project for Comp Cams was to help develop a valvetrain package for the 7.3 Godzilla. I was responsible for everything other than the camshaft, so that meant springs, retainers, locks, limiter and lockout plugs, and testing the engine on a dyno. I developed spring seats to make the installed height correct for a 7230 conical spring, and designed a limiter and lockout plug for the factory cam phaser. After designing and sourcing these components, I wrote a detailed test plan and tested the components in house as well as at an outside testing facility. The three cam kits work very well and are available for purchase.