Caterpillar Reman

— MECHANICAL ENGINEER INTERN —

Starting in the summer of 2017, I worked as a CO-OP for Caterpillar Reman in Corinth, MS. I worked for them during the Summer 2017 semester, Spring 2018 semester, and Fall 2018 semester.

Summer 2017 Highlight

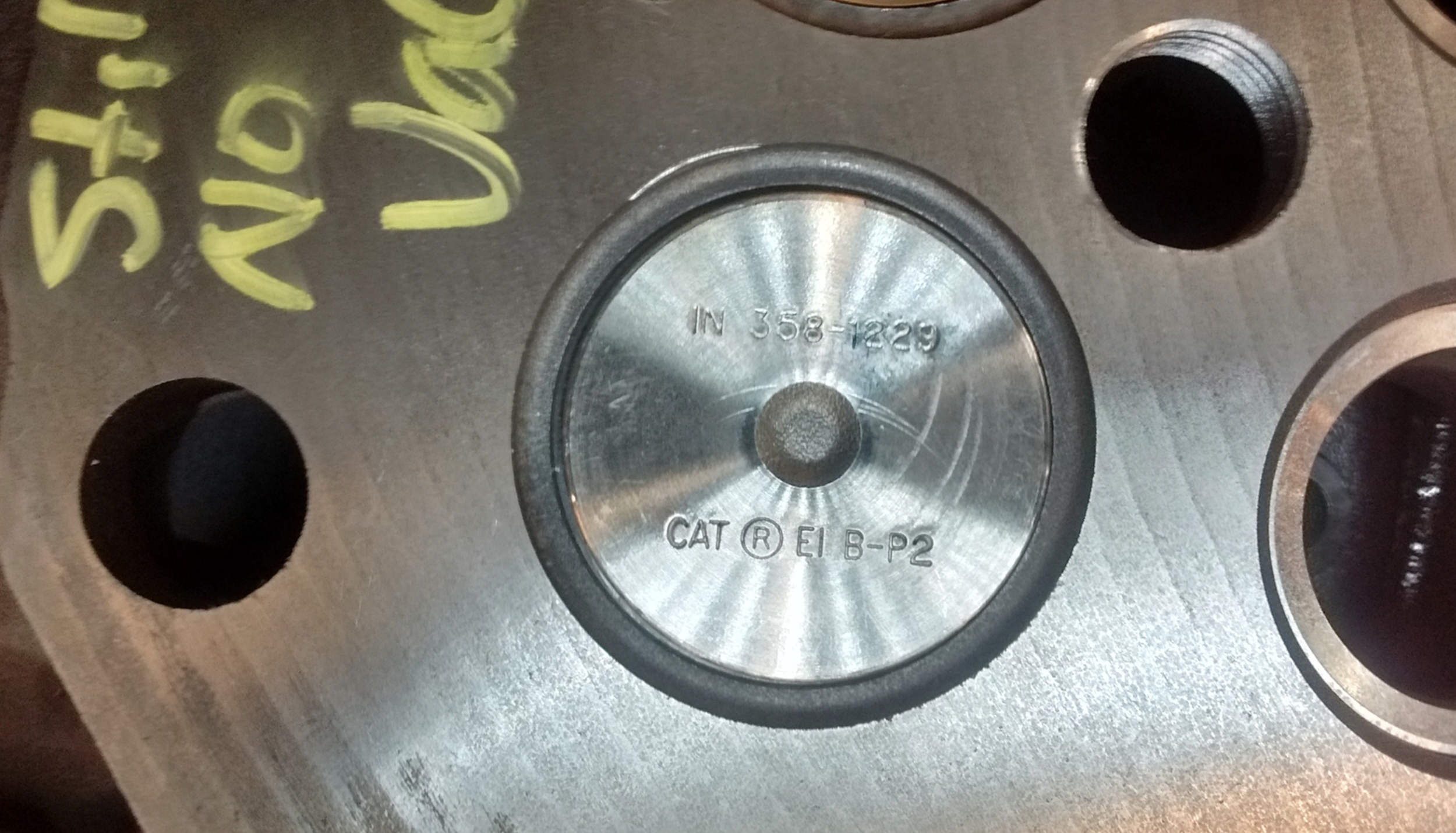

My first term was in the cylinder head department in the. There was a problem in V-12 cylinder head machining that was causing 80% of the machined heads to fail the valve seat leak test, causing a major backup of V-12 engines being built. After checking concentricity and parallelism of the valve seats I realized we had severe issues with the consistency of the machining process. The root cause of these failures was a poorly maintained machining center and CNC programs that were not optimized for the machine being used. Myself and a CNC programmer changed the valve seat machining process and re-machined the fixtures for the heads to take as much variation out as possible. The results were a reduction in scrap rates from 80% to 30%.

Spring 2018 Highlight

My second term was in the disassembly and machining department. I made autoCAD drawings for many of the lifting devices in the area as well as designed new lifting devices for new processes. I also designed a C-clip installation tool for a gear assembly line. This C-clip had a inside diameter at fully expanded bigger than the outside diameter at fully compressed which made a standard C-clip installation tool not an option. After some design iterations, I came up with a collapsable press head that was wide enough to push the C-clip at fully expanded and would collapse to small enough to press the C-clip into the gear.

Fall 2018 Highlight

My third term was in the large engine assembly plant. I worked on several projects dealing with engine machining and assembly, but the most notable project was mold design of the grip green safety grips. The driving force behind this project was developing a culture of proper hand placement when using various lifting devices throughout the plant. With the development of green hand placement grips, it became more apparent to the operator where to put their hands during a lift to reduce pinch point injuries. The grips had several design constraints that had hindered the project in the past, but with my 3d modeling and design skills, we were able to create a solution that met all the design requirements. It had to be removable, of course it had to have good grip, it had to have the cat part number on it, it had to say grip green, and it had to endure the tough manufacturing environment. After a few design iterations, I designed a removable grip for 9/32 chain, 2" flat bar, 1/2" round bar, 3/4" round bar, and 1" round bar. Grip green hand placement devices are now on most lifting devices in the plant and hopefully will be Caterpillar wide soon.