24hrs of Lemons Beemer

— HOW I BUILT A LEMONS CAR —

If you are reading this far into my portfolio, you probably know what 24 Hours of Lemons is. But if you don’t, 24 Hours of Lemons is the largest endurance racing series on the planet. It consists of cheap cars racing around full size road course tracks all across the US with minimal modifications. Our car was built from the ground up by myself and Jerry Thomas, the owner of Thomas Brothers Fabrication. The 540i was a originally bought to be a daily driver, but that clearly wasn't meant to be. At our first event (Barber Motorsports Park 2023), we passed tech on the first try and the car had no mechanical issues all weekend. We placed 47th out of 118 with a fastest lap time of 1:52.5s.

Car’s HISTOry

In the Spring of 2020, I bought the 540i off of Facebook marketplace in hopes of it replacing the 525i that I had lost a few months prior. The original owner had informed me that the only thing needing to replaced was the MAP sensor. But, in typical marketplace fashion, this was not the case. After buying the car, I realized that the timing chain was completely demolished. The oil filter was filled with glitter.

Being the person that I am, I saw this as an opportunity to rebuild the engine. Anyone can imagine that rebuilding a blown 540i was not an easy task. There was definitely a learning curve, but I was still able to complete the task. (More details on the engine build can be found below.)

Once the engine was rebuilt (Fall 2020) and passed the massive burnout test, it was ready to be dailyed as originally planned. Fast forward only 2 weeks, I totaled the 540i by hitting a deer on my way to work one morning. God clearly had other plans.

After the wreck, I parked the car with plans to replace the front-end but the timing was never right. Soon after, I accepted the job at Edelbrock and had to move across the state. A friend of mine allowed me to store the 540i at his place til I figured out a new plan for it. Two years went by and I had lost hope of ever using this car again.

In Summer of 2022, a couple of friends and I discussed competing in the 24 Hours of Lemons. As it turned out I had the perfect car just sitting in a field waiting to be raced. There were a lot of doubts surrounding the performance of this car due to the amount of time it had been sitting in a field, but we accepted the challenge and never looked back.

ENGINE

Block Machining

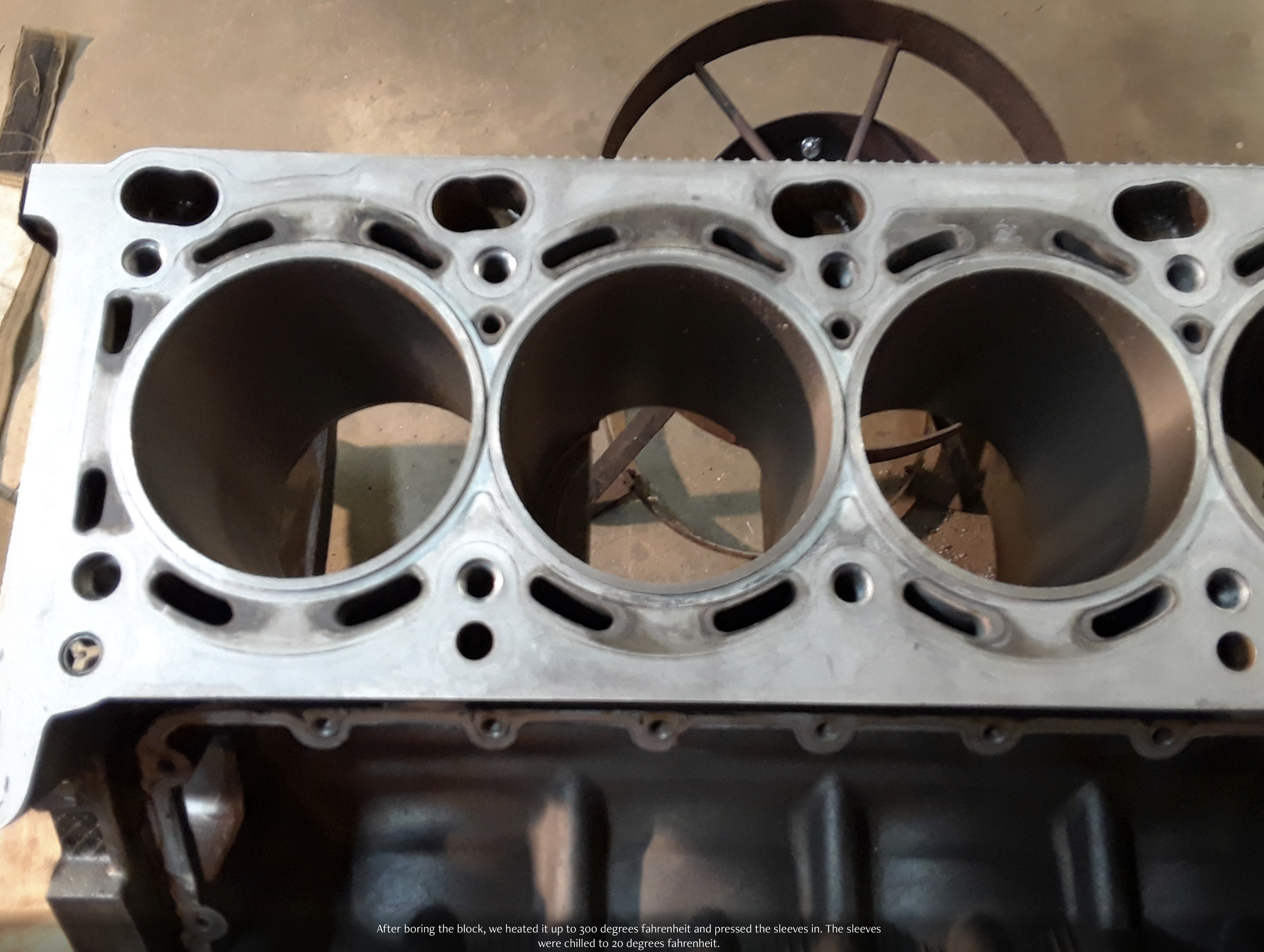

M62B44 engines are made from a material called "alusil." It is basically aluminum that is hard enough to create a cylinder suitable for a piston to travel in. Alusil works well in stock applications, but for the amount of abuse I intend to throw at it, sleeves are a much better choice. To put sleeves in the block, I bored out the cylinders slightly smaller than the outside diameter of the sleeve at room temperature. Then I heated the block to 300°F and pressed the chilled sleeves into each cylinder. There is a step at the bottom of the cylinder to capture the sleeve and further keep it from moving in the block. When the timing chain broke, it broke a molded stud on the front of the block. To fix that we machined a stud that matched the other studs and threaded it into the block using JB weld to secure it in place.

Head Work

When the timing chain broke it bent several valves which had to be found and replaced. To find the valves, we used bluing compound on the seat and spun the valve around on the seat. If the valve had good contact for 360 degrees it was good, if not it was replaced. The heads were coated in easy off oven cleaner and pressure washed several times to clean them up. Then, we polished the valves and cylinders before reassembly. Normally I would port and polish the cylinders but time and money didn't allow that.

Engine Assembly

Since there isn’t a readily available assembly manual for the M62 engine, I used bits and pieces of information I found online along with my best guess for torque values and procedures. I do admit, it took several tries to get the camshafts all timed correctly, but I kept at it and finally assembled the engine correctly. I was inexperienced at building engines when I built this one and always assumed it wouldn’t last very long, but so far it has close to 1000 race miles on it with no signs of stopping. I unfortunately don’t have any pictures of the assembly, I was more focused on building the engine correctly.

Meeting Lemon’s requirments

To compete in lemons, we had to build a race car that would pass technical inspection. Jerry Thomas and I read the rules several times and built the cage to the required specifications. After the cage was finished, we installed the safety equipment and replaced all the required body panels to pass tech. There are no rules on how much weight you can take out of the car, so we cut every ounce out we could find. A stock 2000 540i weighs 3850 pounds, and our car with a full 1.75” .120 wall cage and all the required safety gear weighs 2840 wet.